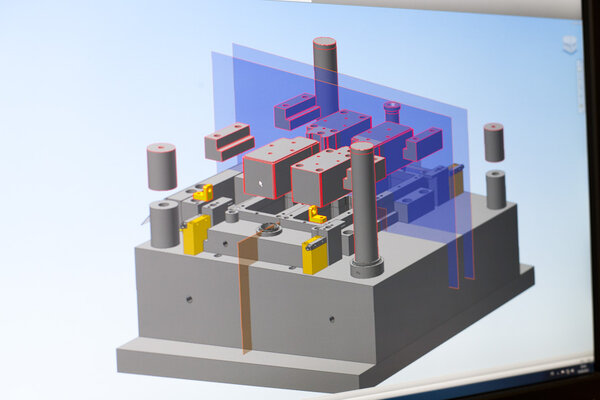

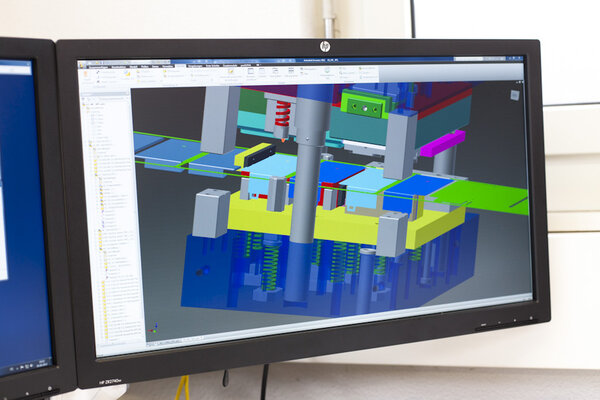

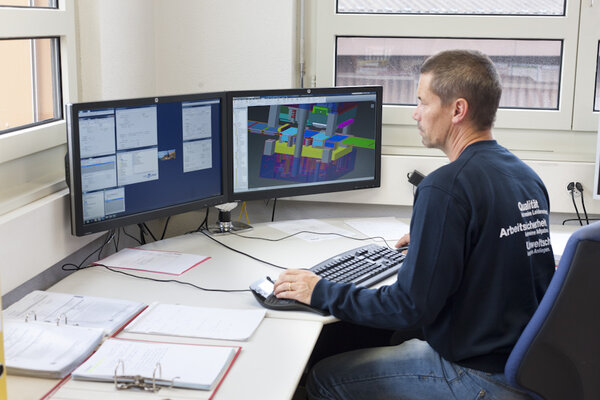

After we have specified your requirements, we create the plans for the tool construction in the construction department. Here the course is set for later production. The progressive dies or deep-drawing dies used for stamping are designed and developed by our qualified designers with many years of experience. Through innovation, coupled with modern and advanced CAD-3D software (AutodeskInventor), WKK is able to simulate data within the shortest possible time and thus greatly reduce manufacturing costs. We always have only one goal in mind: to produce an optimal tool of the highest quality.

Articles on the subject

Swiss machinery market, 8 August 2012The design of the punching tools plays a key role at WKK. This is where the decision is made as to how economical the stamping and bending process for the sheet metal part will be. Time-to-market process reduced by 50%!144 KB

Swiss machinery market, 8 August 2012The design of the punching tools plays a key role at WKK. This is where the decision is made as to how economical the stamping and bending process for the sheet metal part will be. Time-to-market process reduced by 50%!144 KB

Construction Manager

If you have any constructive questions, Horst Schrepfer is the right contact person to support you in developing sheet metal parts.

Horst Schrepfer

Construction Manager

Technician HF Mechanical Engineering

Tel. +41 55 293 21 26

h.schrepfer@wkk.ch