We can offer you complete solutions thanks to a wide selection of welding processes, rational assembly equipment and, last but not least, our highly qualified staff. WKK assembles its own parts as well as parts produced by third parties into ready-to-install assemblies. After assembly, we inspect and pack the components on time, in the highest quality and in the right quantity.

| Number | Proceedings | Designation |

| 1 | punching hydr | LAUFFER 100 tons hydraulic C-press |

| 1 | punching hydr | LAUFFER 100 to hydraulic frame press |

| 2 | punching hydr | JOSSI 10 tons hydraulic C-press |

| 1 | punch mech | TOX fine press |

| 1 | weld | TECNA small projection welding machine |

| 1 | weld | RESISTRONIC impulse welding machine |

| 1 | weld | KVT stud welding machine |

| 2 | weld | KEMPPI TIG/MIG (round) welding machine |

| 1 | rivets | BALTEC large riveting machine |

| 1 | rivets | BALTEC small riveting machine |

| 1 | assemble | WKK Welding and punching combination unit |

| 4 | assemble | Mount the ASSEMBLY |

| 3 | assemble | ASSEMBLY straightening/checking |

| 1 | Q-examine | DeMeet (Check) |

| 1 | Q-examine | KEYENCE IM6225 Digital Profile Projector |

| 3 | Q-examine | altimeter |

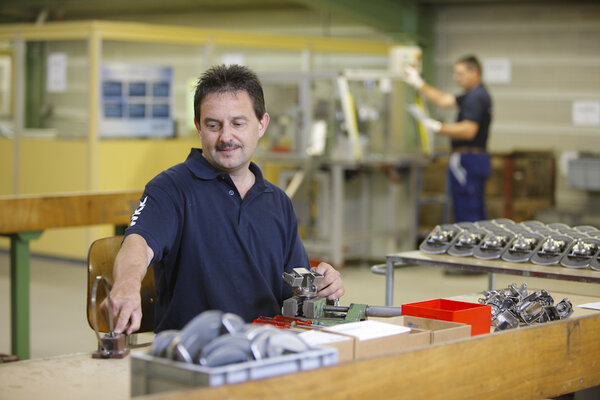

Production Manager

More than 25 employees are employed in the production of stamped parts. Roland Gohlisch coordinates our production so that the specified goals, deadlines and quality specifications are implemented in a sustainable manner.

Roland Gohlisch

Production Manager

Phone +41 55 293 21 82

r.gohlisch@wkk.ch